Mushroom farming in Kenya is a high-yield agribusiness for 2026. offering returns of up to KES 150,000 every 8 weeks on a low-budget setup. By utilizing locally available materials like mud and grass thatch for housing. smallholder farmers can drastically reduce startup costs while growing high-demand varieties like the white button mushroom. This guide provides a complete roadmap. from constructing a simple KES 20,000 mud structure to accessing the lucrative Nairobi retail market.

Table of Contents

What are the most profitable mushroom varieties for Kenyan farmers in 2026?

The White Button Mushroom (Agaricus bisporus). remains the most profitable, commanding 90% of the commercial market with retail prices hitting KES 600-1,000 per kg. For 2026, the new “warm weather” button variety (Agaricus bitorquis) from JKUAT is a game-changer. allowing cultivation in warmer regions like Kajiado and Machakos without expensive climate control.

Module A: Technical Deep-Dive & Best Varieties

Success in mushroom farming begins with selecting the right genetic strain for your specific local climate. While Oyster mushrooms are easier for beginners. Button mushrooms offer significantly higher financial rewards due to their massive demand in the hospitality and retail sectors. Royal Seedlings advises beginners to start with robust strains that can withstand minor temperature fluctuations.

1. White Button (Agaricus bisporus): This is the industry standard, preferred by major supermarkets like Naivas and Carrefour. It requires a strictly cool environment between 15°C and 20°C to thrive. Farmers in Kiambu and Nyeri are best positioned for this variety due to natural climatic advantages.

2. Warm Weather Button (Agaricus bitorquis): A critical innovation for the 2026 farming season. This variety thrives in temperatures of 25°C – 26°C, making it ideal for lower altitude areas. It opens up mushroom farming to regions previously considered too hot, such as parts of Eastern Province and Nyanza, eliminating the need for costly air conditioning units.

3. Crimini (Brown Button): Often marketed as “Portobello” when mature, these have a firmer texture and longer shelf life. They are gaining traction in high-end Nairobi restaurants but require the same cool conditions as the standard white button. Their darker cap color hides minor bruising better than white varieties, reducing waste during transport.

Biological Considerations for Selection

Farmers must understand that mushroom varieties are not just about market preference but biological compatibility. The White Button requires a thermal shock to initiate pinning, which means you must drop the temperature drastically after colonization. If your region stays constantly hot, this trigger will fail without refrigeration.

Read Also: Azolla Farming in Kenya: Cheap Animal Feed and Higher Profits in 2026

Conversely, Agaricus bitorquis is resistant to viral diseases that often plague the standard button mushroom. It has a tougher skin, which makes it more resilient during rough transport on rural roads. KALRO researchers suggest this variety for farmers located more than 100km from their primary market.

Yield potential also varies significantly between these strains. Standard buttons can yield up to 10kg per square meter under optimal conditions. The warm-weather variety typically yields slightly less, around 7-8kg per square meter, but the savings on electricity offset the lower volume.

Where to Buy Mushroom in Kenya 2026:

Sourcing quality inputs is the biggest hurdle. For 2026, certified spawn (seeds) should be purchased directly from government research bodies like KALRO or universities like JKUAT to avoid contamination. Private suppliers like Royal Seedlings and other established nurseries offer verified substrate and casing soil, often with accompanying agronomy support.

Module B: Sourcing & Procurement Strategy

The quality of your “seed” (spawn) dictates 80% of your harvest success. Poor quality spawn leads to the dreaded “green mold” contamination, wiping out entire crops before they even fruit. You must establish a relationship with a supplier who guarantees the freshness of their laboratory cultures.

JKUAT (Juja Campus): They are the primary source for the new Agaricus bitorquis warm-weather spawn. They sell 1-liter bottles for approximately KES 600. It is advisable to book your order two weeks in advance as demand often exceeds supply.

KALRO (Kabete/Thika Centers): These centers are reliable for standard white button spawn and sterilized casing soil. Their spawn is produced under strict sterile conditions, reducing the risk of genetic mutations. They also offer short training courses for beginners which can be invaluable.

Royal Seedlings: This private entity is known for offering comprehensive starter kits that include spawn, ready-to-use substrate, and training manuals. They are excellent for farmers who want a “plug-and-play” solution without sourcing individual components. Their agronomy support helps troubleshoot issues via WhatsApp.

Digifarm / Mkulima Young: These are useful digital platforms to find second-hand equipment like knapsack sprayers or drums. However, you must never buy spawn from unverified sellers on these platforms due to high contamination risks. Use these sites strictly for hardware and non-biological inputs.

Essential Equipment Sourcing

Beyond spawn, you need specific hardware to run a mushroom house efficiently. A good quality Knapsack Sprayer is essential for misting, and it must never have been used for toxic pesticides. You can buy these at any agro-vet in Nakuru or Eldoret for about KES 3,000.

Thermometers and Hygrometers are non-negotiable tools for monitoring climate. Do not rely on “feeling” the temperature; digital meters are available at Jumia or hardware shops in Industrial Area. You need a “Min-Max” thermometer to see how cold it got at night.

For substrate preparation, you will need heavy-duty spade forks and black polythene sheets. The polythene is used for covering the compost pile to generate heat. Ensure the gauge is heavy (1000 gauge) to prevent tearing during the turning process.

Which Kenyan counties are best suited for low-budget mushroom farming?

Kiambu County is the top performer due to its proximity to Nairobi‘s market and naturally cool climate, reducing cooling costs. Meru County is emerging as a strong competitor with excellent availability of wheat straw substrate. However, with new heat-tolerant varieties, Kajiado is becoming a viable low-cost option for 2026.

Module C: Regional Comparative Analysis (2026)

1. Kiambu County (The Market Hub)

Kiambu remains the “Silicon Valley” of Kenyan mushroom farming. The high altitude ensures temperatures naturally stay within the 18°C-22°C range, meaning a simple mud house with cross-ventilation is often sufficient.

Advantage: You are less than 30km from 60% of Kenya’s premium mushroom buyers, such as Westlands hotels and Karen grocers.

Challenge: High cost of land and labor compared to rural counties.

2. Meru County (The Substrate King)

Meru is a wheat-growing giant, providing an endless supply of raw materials. Wheat straw is the primary ingredient for mushroom compost (substrate). While a farmer in Nairobi pays KES 300 per bale of hay, a Meru farmer can often source it for free or at a nominal transport cost.

3. Kisii/Nyamira (The Wet Highland)

High humidity is a blessing for mushrooms, and Kisii offers this year-round. The region’s damp climate reduces the need for constant floor watering to maintain humidity.

Advantage: High natural humidity (80%+) lowers water usage and labor.

Challenge: Road infrastructure can be tricky in rainy seasons, potentially delaying fresh produce delivery.

Emerging Frontiers: Uasin Gishu & Nakuru

Uasin Gishu is the breadbasket of Kenya and has massive potential for mushroom farming due to straw abundance. Farmers here often burn wheat straw as waste, representing a missed opportunity for virtually free substrate. The cool nights in Eldoret are perfect for the fruiting stage of button mushrooms.

Nakuru County offers a strategic middle ground between production and market. With a growing middle class in Nakuru town and Naivasha, local demand is rising. The climate is slightly warmer, requiring more careful ventilation management in the mud house design.

Read Also: 10 Most Profitable Farming Ventures in Kenya for 2026

Farmers in Machakos and dry areas must invest heavily in water storage. While the warm-weather variety grows there, humidity control is the battle. A low-budget house in these areas must have a “drip kit” installed on the roof thatch to keep it constantly wet for evaporative cooling.

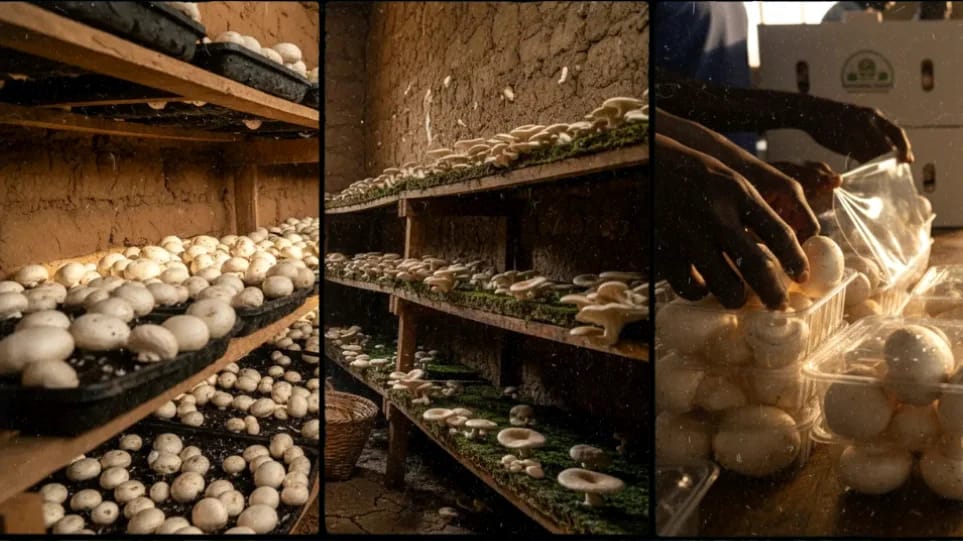

How do I construct a low-cost mushroom house in Kenya?

A 15ft x 20ft mud house is the most cost-effective structure, costing between KES 20,000 and KES 50,000. Use mud walls for thermal insulation and a grass-thatched roof to regulate heat. The floor should be earthen (compacted soil) or simple screed to retain humidity. Install dark polythene sheets on windows to control light and wire mesh to prevent insect entry.

Module D: Step-by-Step Construction Guide

The goal of the structure is to create a “cave-like” environment: cool, dark, and humid. Concrete blocks retain heat, which is bad for mushrooms, whereas mud walls breathe and insulate against the midday sun. This guide assumes a standard 15ft by 20ft footprint.

Step 1: The Foundation & Framework

Dig a shallow trench for the foundation and fill it with rocks for stability. Erect sturdy poles (Blue Gum or treated Wattle) spaced 3 feet apart. Ensure the roof height is at least 8 feet to allow hot air to rise away from the growing shelves.

Step 2: Mud Walling (The Insulation Layer)

Use a mixture of red soil, water, and chopped dry grass to create the mud daub. The walls should be at least 6 inches thick to provide adequate thermal mass. Plaster the inside smoothly with a mix of mud and cow dung to seal cracks where insects might hide.

Step 3: Roofing (The Heat Shield)

Avoid iron sheets (mabati) unless you have a ceiling, as they turn the house into an oven. A thick grass thatch roof (minimum 6 inches) is the best low-budget insulator. Ensure the roof overhangs the walls by 1 meter to protect the mud walls from heavy rain erosion.

Step 4: Internal Shelving

To maximize space, you must grow vertically. Construct wooden shelves using off-cuts, leaving a 60cm vertical gap between shelves. A 15x20ft house can accommodate three rows of shelves, with each row having 3 to 4 vertical tiers.

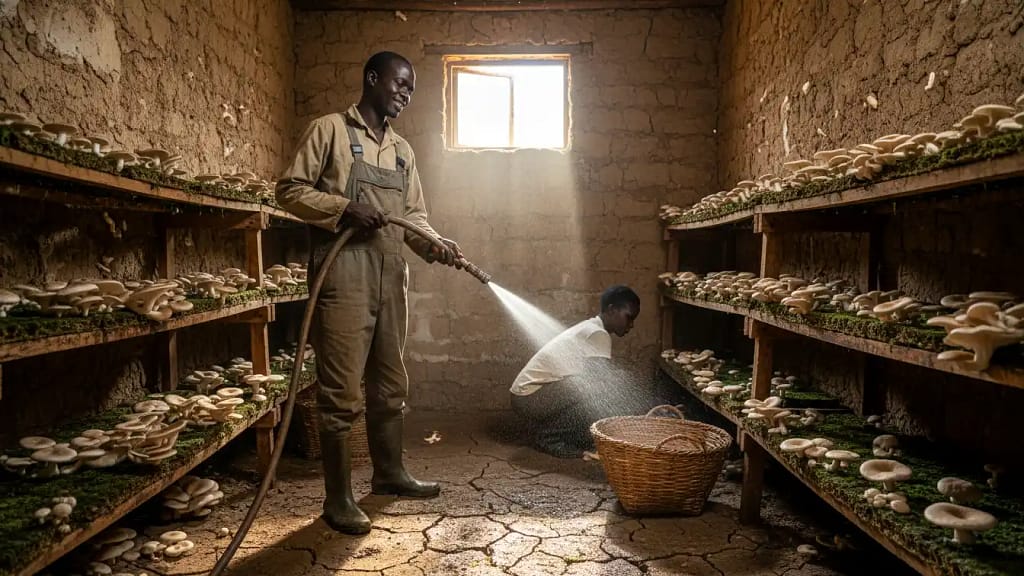

Ventilation and Pest Proofing

Mushrooms breathe oxygen and exhale Carbon Dioxide (CO2), just like humans. You need two windows on opposite walls to create cross-ventilation. Cover these windows with fine insect netting (mosquito mesh) to keep out Sciarid flies.

Add a “double door” system or a footbath at the entrance. A simple plastic basin with water and Dettol or bleach acts as a footbath to kill pathogens on shoes. Never allow direct sunlight to hit the mushroom beds; use black polythene curtains over the windows.

The floor should remain earthen or be covered in river sand. You will water this floor daily to keep the humidity high. A concrete floor dries out too quickly, making it harder to maintain the required 85-90% humidity levels.

What is the composting and substrate process for button mushrooms?

Substrate preparation is the most technical phase, involving the composting of wheat straw and chicken manure for 21-28 days. This process breaks down complex carbohydrates into food for the mushrooms. The compost must be turned every 3-4 days to aerate it and prevent anaerobic rotting, followed by pasteurization to kill pests.

Module E: The Agronomy Process

Phase 1: Pre-Wetting and Mixing

Start by soaking your wheat straw thoroughly with water for 2-3 days until it is soft. Mix the wet straw with chicken manure (rich in nitrogen) and gypsum (stabilizes pH). A standard ratio is 1 ton of straw to 300kg of manure and 30kg of gypsum.

Phase 2: The Composting Pile

Stack the mixture into a high, narrow pile to allow it to heat up naturally. The center of the pile should reach 65°C-75°C, which kills weed seeds and bad bacteria. Turn the pile manually every 3 days, moving the outside material to the inside to ensure even cooking.

Phase 3: Pasteurization (The Kill Step)

Before planting, the compost must be pasteurized to kill nematodes and mites. In a low-budget setup, you can steam the compost in a modified metal drum (200L) over a fire. The steam must pass through the compost for at least 4-6 hours at 60°C.

Spawning and Casing

Once the compost cools to 25°C, mix in the spawn (seeds) thoroughly. Pack the compost into bags or lay it directly on the wooden shelves, compressing it slightly. Cover the shelves with newspaper and keep them moist to allow the white mycelium to colonize the dark compost.

After about 14 days, the compost will turn white with mycelium. You must now apply the “casing soil”—a layer of sterilized loam soil and agricultural lime. This layer acts as a water reservoir and supports the heavy mushrooms; without it, you will get vegetative growth but no fruit.

Maintain the temperature at 20°C-24°C during this vegetative phase. Once the casing soil is colonized (about 10 days later), drop the temperature to 16°C-18°C and introduce fresh air. This “cold shock” tells the fungus that winter is coming, triggering it to produce mushrooms for reproduction.

Is mushroom farming in Kenya profitable in 2026?

Yes, a well-managed 15ft x 20ft unit can generate a net profit of KES 80,000 – 120,000 per cycle (2 months). With a break-even point typically reached after the second cycle, the Return on Investment (ROI) is high compared to traditional crops like maize. However, profits depend entirely on direct marketing to retailers rather than selling to middlemen.

Module F: Deep-Dive Financials (Standard 15x20ft Mud House)

This financial model is based on a low-budget “Mud & Thatch” structure housing 400 bags of Button Mushrooms. Prices are estimated for 2026 KES and reflect the current inflation rates in the agricultural sector. These figures assume you own the land.

Read Also: Maize Farming in Kenya: High Yield Production Guide, Best Practices and Profit Tips 2026

1. One-Off Startup Costs (Infrastructure)

| Item | Description | Cost (KES) |

|---|---|---|

| Mud House Structure | Labor, poles, mud, grass thatch (15x20ft) | 35,000 |

| Shelving (Timber) | Wood off-cuts and posts for vertical shelves | 15,000 |

| Equipment | Knapsack sprayer, thermometer, hygrometer | 5,000 |

| Sterilization Drum | 200L metal drum for pasteurizing substrate | 3,500 |

| TOTAL CAPEX | One-time investment | 58,500 |

2. Recurring Operational Costs (Per Cycle – 2 Months)

| Item | Quantity / Details | Cost (KES) |

|---|---|---|

| Substrate (Compost) | Wheat straw, chicken manure, gypsum (1 ton) | 15,000 |

| Button Spawn | 30 Liters @ KES 600/L | 18,000 |

| Casing Soil | Treated soil + lime | 4,000 |

| Labor | Casual labor for composting/packing | 8,000 |

| Miscellaneous | Water, firewood, packaging punnets | 5,000 |

| TOTAL OPEX | Cost per crop cycle | 50,000 |

3. Revenue & Profit Analysis

| Metric | Calculation | Value (KES) |

|---|---|---|

| Expected Yield | 400 bags x 2.5 kg per bag (conservative) | 1,000 kg |

| Spoilage Rate | 10% loss due to handling/unsold stock | -100 kg |

| Net Saleable Volume | 900 kg | 900 kg |

| Average Price | Wholesale/Retail blend (KES 500/kg) | KES 500 |

| GROSS REVENUE | 900 kg x KES 500 | 450,000 |

| NET PROFIT | Revenue (450k) – Opex (50k) | 400,000 |

Note: The net profit of KES 400,000 assumes a very high success rate and direct retail sales. A beginner should target a conservative net profit of KES 150,000 – 200,000 for the first two cycles as they learn pest management and climate control.

Analysis of Profit Margins

The single biggest cost driver is the spawn. By learning to produce your own spawn (which requires a lab setup), you can reduce your operational costs by 35%. However, for a beginner in a mud house, buying certified spawn is safer than risking contamination.

Labor costs can be minimized if the farm is family-run. Composting is the only physically demanding stage that might require hiring casuals. Harvesting requires finesse and hygiene but can be done by one person for a 400-bag unit.

Energy costs in this model are near zero because we are not using air conditioning. This is the “Low Budget” advantage. A high-tech farm spends KES 50,000 per month on electricity alone, whereas the mud house relies on passive cooling from the thatch roof.

How can I add value to my mushroom harvest in Kenya?

Value addition extends shelf life and increases margins by 40%. Simple methods for beginners include drying mushrooms for long-term storage. creating “Mushroom Crisps” (deep-fried and spiced), or processing them into mushroom powder for soups and porridge fortification. Packaging fresh buttons in branded 250g punnets significantly boosts retail appeal over selling in bulk.

Module G: Supply Chain & Value Addition

The fresh mushroom supply chain is a race against time. Fresh button mushrooms lose quality within 3-4 days at room temperature. To maximize income, you must control the chain or add value before spoilage occurs.

1. Fresh Packaging (The Retail Standard):

Don’t sell in generic nylon bags. Invest in 250g clear plastic punnets (approx. KES 10 each) and cling film. A branded sticker with your farm name and “Harvest Date” builds immense trust with customers.

2. Solar Drying (Shelf Life Extension):

During market gluts (oversupply), don’t throw away produce. Slice the mushrooms and dry them in a simple solar dryer. Dried mushrooms retain their flavor and can be sold to institutions or export brokers.

3. Mushroom Powder (The Health Market):

Pulverize dried mushrooms into a fine powder. This is a high-value product sold to parents for fortifying baby porridge (uji) or to health enthusiasts for smoothies. It requires zero refrigeration and can be shipped nationwide via courier services.

Marketing to the Kenyan Consumer

Kenyan consumers are increasingly health-conscious and looking for meat alternatives. Position your mushrooms as a “Superfood” rich in protein and immune-boosting properties. Use WhatsApp groups to target estate communities in Syokimau, Roysambu, or Langata.

Approach local pizzerias directly. Pizza joints use huge volumes of toppings and often prefer buying fresh from a local farmer than frozen imports. Offer them a free sample first; quality speaks louder than a sales pitch.

Do not ignore the “Mama Mboga” network. While they buy in small quantities, they pay cash daily. Supply 5-10 stalls in your local market to ensure you have a steady cash flow while waiting for larger hotel orders.

Read Also: Pixie Orange Farming in Kenya 2026: Complete Guide to Seedlings, Costs and Profit per Acre

Module H: 12-Month Farming Calendar

Mushroom farming is not seasonal; it is cyclical. A well-managed low-budget unit can achieve 5 to 6 cycles per year. This calendar assumes a standard 8-week cycle (2 months) for Button Mushrooms.

- January – February (Cycle 1):

- Activity: Composting and spawning.

- Context: Jan is hot; ensure your thatch roof is thick (6 inches+) to keep the interior cool.

- March – April (Cycle 1 Harvest / Cycle 2 Start):

- Activity: Harvesting Cycle 1, casing Cycle 2.

- Context: Long rains begin. Monitor humidity closely and ensure the roof overhang protects the mud walls.

- May – June (Cycle 2 Harvest / Cycle 3 Start):

- Activity: Peak production. Market prices stabilize.

- Context: Coolest months. Ideal for high yields of White Button mushrooms; minimize ventilation to retain warmth.

- July – August (Cycle 3 Harvest / Cycle 4 Start):

- Activity: Cold season maintenance.

- Context: Add heating if necessary (charcoal jiko with chimney). Mushrooms grow slower but are denser and heavier.

- September – October (Cycle 4 Harvest / Cycle 5 Start):

- Activity: Preparation for short rains.

- Context: Sterilize house thoroughly between cycles to prevent disease buildup as humidity fluctuates.

- November – December (Cycle 5 Harvest / Maintenance):

- Activity: Festive season sales.

- Context: Demand peaks for Christmas. Plan your Cycle 5 to flush exactly in mid-December for maximum pricing power.

2026 Outlook & Conclusion

As we navigate 2026, mushroom farming in Kenya is shifting from a “rich man’s hobby” to a viable mass-market agribusiness. The barrier to entry has lowered significantly with the validation of low-cost mud housing and the availability of heat-tolerant seed varieties. The era of needing millions to start a farm is over.

The future lies in efficiency and marketing. Farmers who rely solely on middlemen will struggle with thin margins. Those who build direct relationships with local pizzerias, hotels, and estate grocers—and who treat their farm as a data-driven business—will thrive.

The KES 20,000 mud house is not just a structure; it is a gateway to a sector that imports over 700 tonnes of mushrooms annually. The market is waiting for local production to fill that gap. Start with one house, master the humidity, and scale up from your profits.

Expert Tip: “Start small. Build one 15x20ft mud house, master the climate control, and secure your first 5 regular customers before expanding. Mushrooms punish greed but reward precision.”

Read Also: How to Grow Big Cabbages in Containers Kenya: Best Varieties, Where to Buy Seeds and Best Farming Practices 2026

Farmers Also Ask (FAQ)

1. Can I grow button mushrooms without a concrete structure?

Yes, absolutely. A mud house with a thick grass-thatched roof is actually superior for temperature control in hot areas compared to a single-walled stone house. The key is ensuring the walls are plastered smoothly (even with mud/cow dung) to prevent insect breeding crevices and the floor is kept damp to maintain humidity.

2. How much water does a mushroom farm need daily?

Button mushrooms are water-intensive but not wasteful. For a standard 15x20ft house, you need approximately 100-200 liters per day for misting the air and watering the casing soil during the fruiting stage. You do not need a river; a standard 2,000L tank is sufficient for a full cycle.

3. What is the biggest disease threat to mushrooms in Kenya?

Green Mold (Trichoderma) is the primary enemy. It appears as green patches on the substrate and spreads rapidly. It is caused by poor hygiene—unwashed hands, dirty tools, or contaminated spawn. Prevention is better than cure; always use a footbath with disinfectant before entering the house.

4. Can I use sawdust instead of wheat straw for button mushrooms?

No. Sawdust is excellent for Oyster mushrooms but poor for Button mushrooms. Button mushrooms require compost made from wheat straw (or hay), chicken manure, and gypsum. The composting process breaks down the straw into a nutrient-rich dark food source that the button mushroom mycelium needs.

5. How do I sell my mushrooms if I don’t have a supermarket contract?

Focus on the “informal” premium market. Visit local pizzerias, Indian restaurants (huge demand for vegetarian options), and independent vegetable stalls in high-income estates. Create a WhatsApp group for your estate and offer “Fresh Farm Delivery” bundles. Selling 50kg directly to neighbors is often more profitable than 200kg to a wholesaler.

6. Is mushroom farming labor intensive?

It is “attention intensive” rather than labor intensive. You don’t need heavy lifting daily, but you need to check the house 3 times a day for humidity and temperature. Harvesting requires gentle handling. One person can easily manage 2 standard mud houses alone.

7. What is the function of the “casing soil”?

Casing soil is a layer of sterile loam applied on top of the colonized compost. It does not provide food; its job is to hold moisture and support the mushroom pins (babies) as they emerge. Without casing soil, button mushrooms will not form fruits.

8. How long does a harvest period last?

The harvesting phase, known as “flushing,” lasts about 4-6 weeks. You will get 3 main “flushes” (waves) of mushrooms, with about 7-10 days of rest between each wave. The first flush is usually the heaviest and best quality.

9. Can I reuse the compost after harvesting?

You cannot use it for mushrooms again, as the nutrients are depleted. However, “Spent Mushroom Substrate” (SMS) is an incredible organic fertilizer for vegetables, sukuma wiki, and maize. You can sell it to other farmers or use it on your own shamba, adding another revenue stream.

10. Why are my mushrooms turning brown or opening too fast?

This indicates high temperatures or over-maturity. If the room is too hot (over 22°C), mushrooms mature rapidly, the caps open, and they lose value. Harvest them while the cap is still tight and closed against the stem. Improving ventilation or watering the floor can help lower the temperature.